Alternatives for removing silicon from lithium hydroxide solutions at the Lithium Chemicals Plant

What we are looking for?

At the SQM Lithium Chemicals plant, the challenge of managing the presence of silicon in the lithium hydroxide solution must be addressed. This phenomenon becomes critical during the evaporation phase. The main impact of silicon is that it causes silicate scaling, which reduces process efficiency, subsequently lowering the production rate, shortening the operational cycle, and increasing the frequency and duration of maintenance. Additionally, the presence of silicon above customer specifications leads to quality rejections of the final product.

A technological solution is required to remove silicon from the lithium hydroxide solution to prevent the formation of scaling and ensure the quality of the final product, which will optimize operational continuity and production costs.

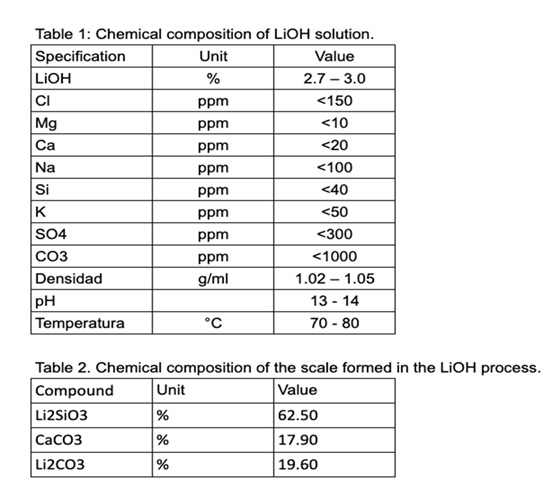

This is the composition of the brine entering the heat exchangers: