Solutions for managing scaling in heat exchangers at the lithium chemical plant

What we are looking for?

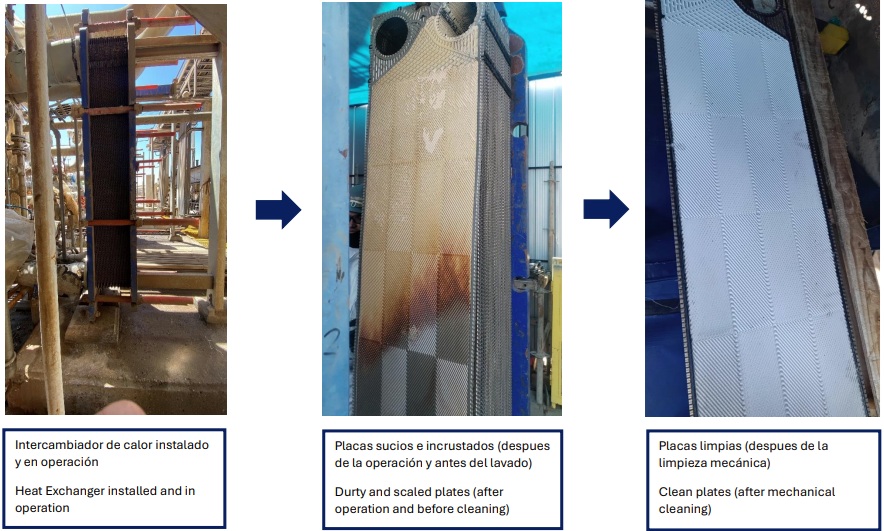

The challenge focuses on improving the efficiency of heat exchangers by preventing the formation of scaling, which affects performance and increases maintenance cost and energy consumption.

The goal is to develop specialized materials and/or auxiliary technologies that prevent scaling and, at the same time, implementing a monitoring system capable of detecting early-stage buildup.

This will enable preventive actions to be taken before the issue significantly impacts system operation.

The solution will benefit key industries by reducing operational costs and extending equipment lifespan.

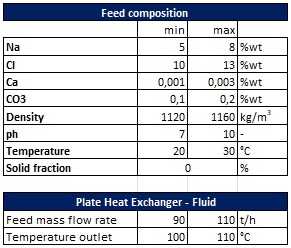

This is the composition of the brine entering the heat exchangers:

How will we evaluate your solution?

In the case of antiscaling materials and auxiliary technologies, the goal is to reduce or even eliminate scale formation in order to minimize the need for cleaning and maintain heat transfer efficiency, resulting in minimal additional steam consumption for the process.

For scale monitoring technologies, the aim is to enable accurate measurement and modeling of scale formation, allowing for data-driven decisions to be made to improve the operational efficiency of the heat exchanger and initiate preventive maintenance measures.